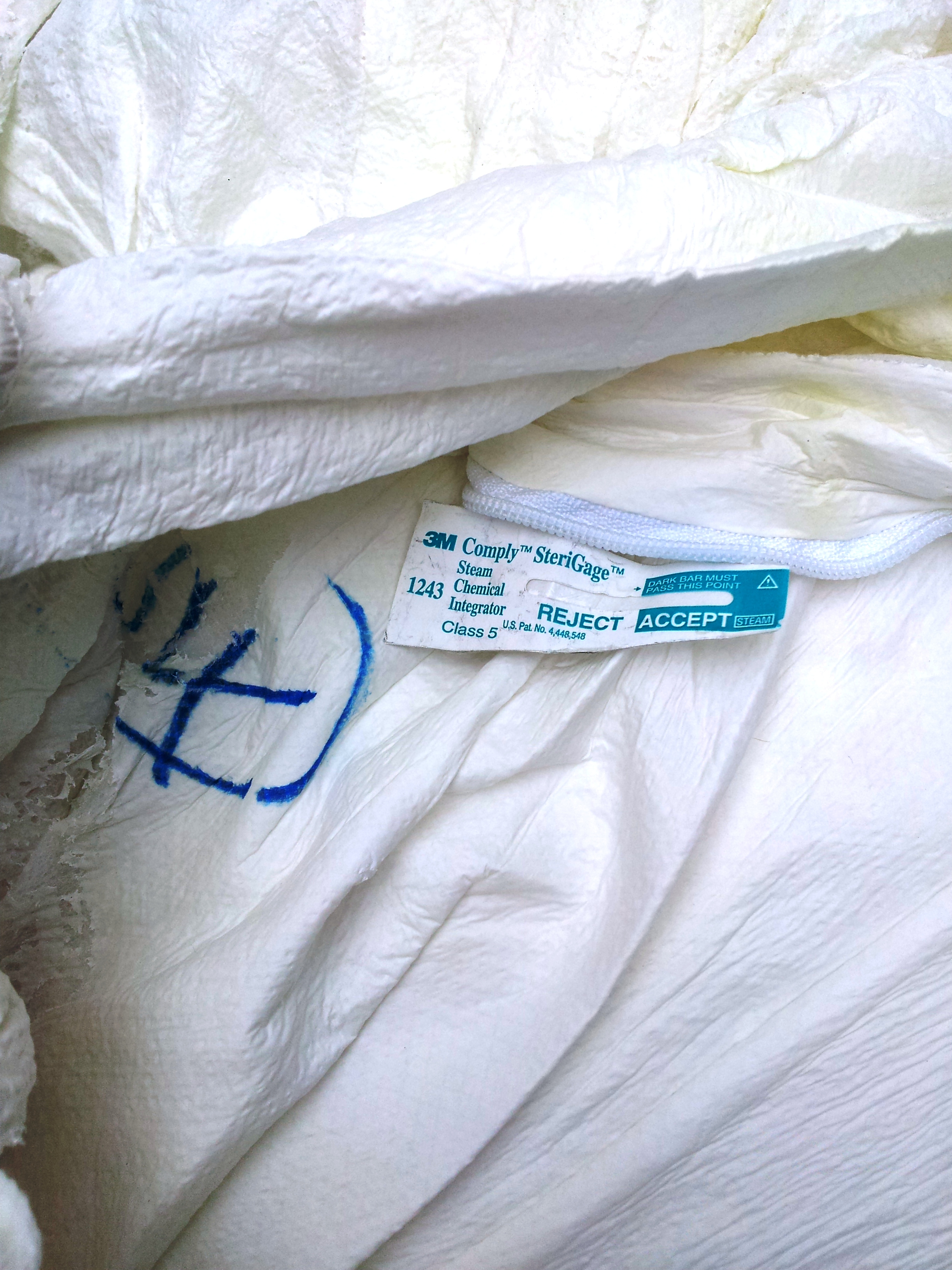

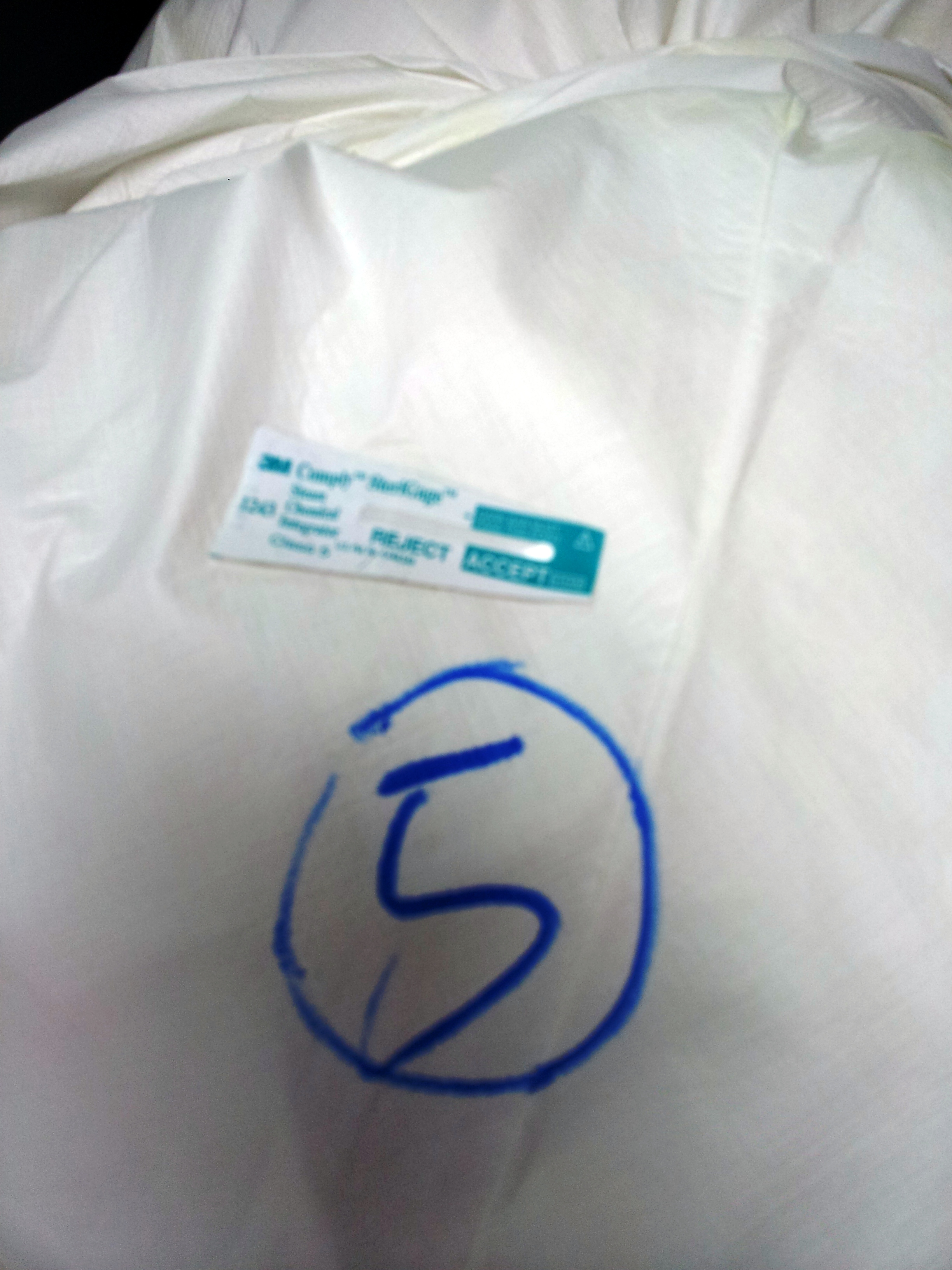

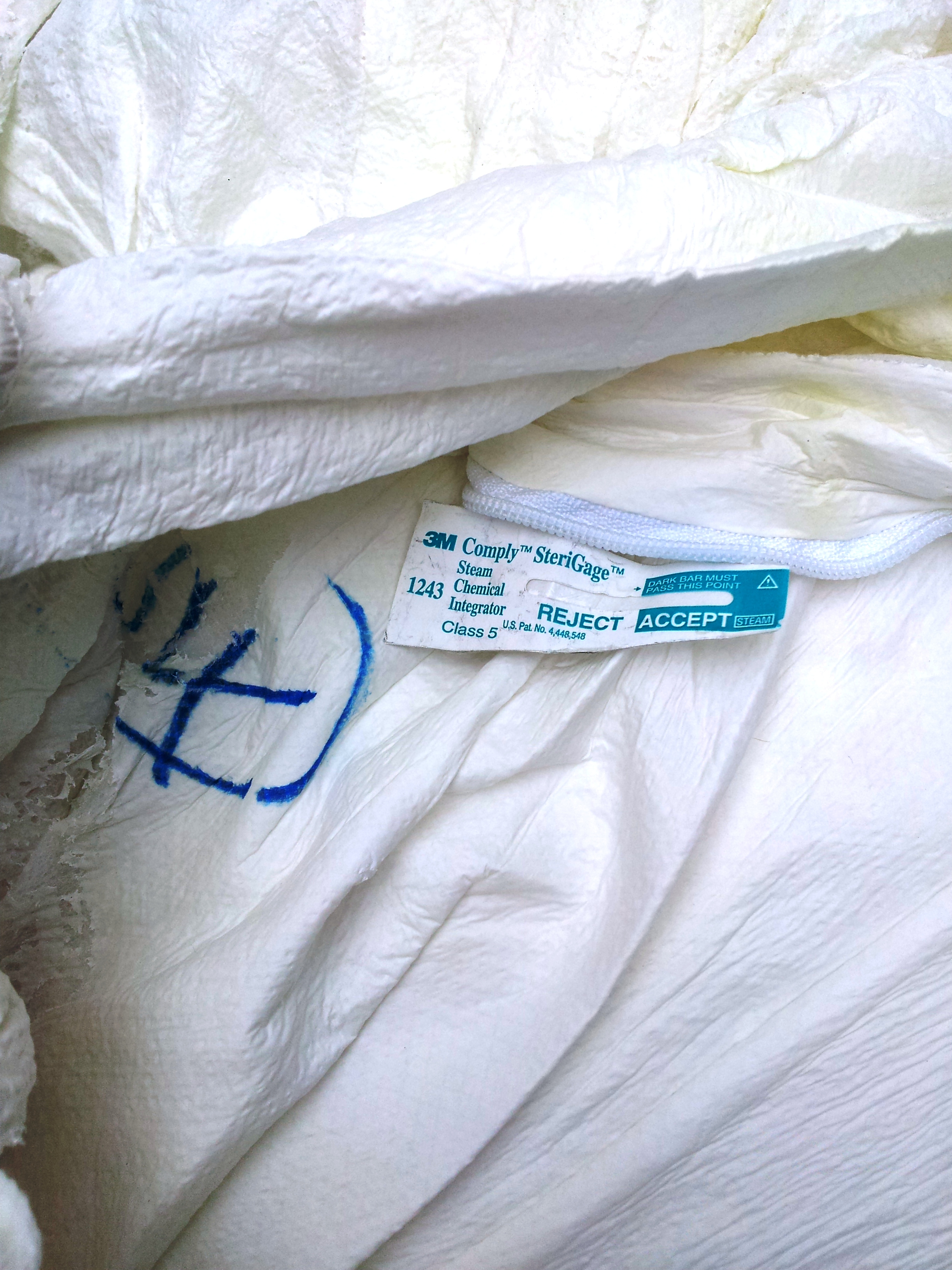

| 50mL tubes containing CI's. One is placed inside of a glove |

Data logger placed inside of a glove |

A second data logger is added |

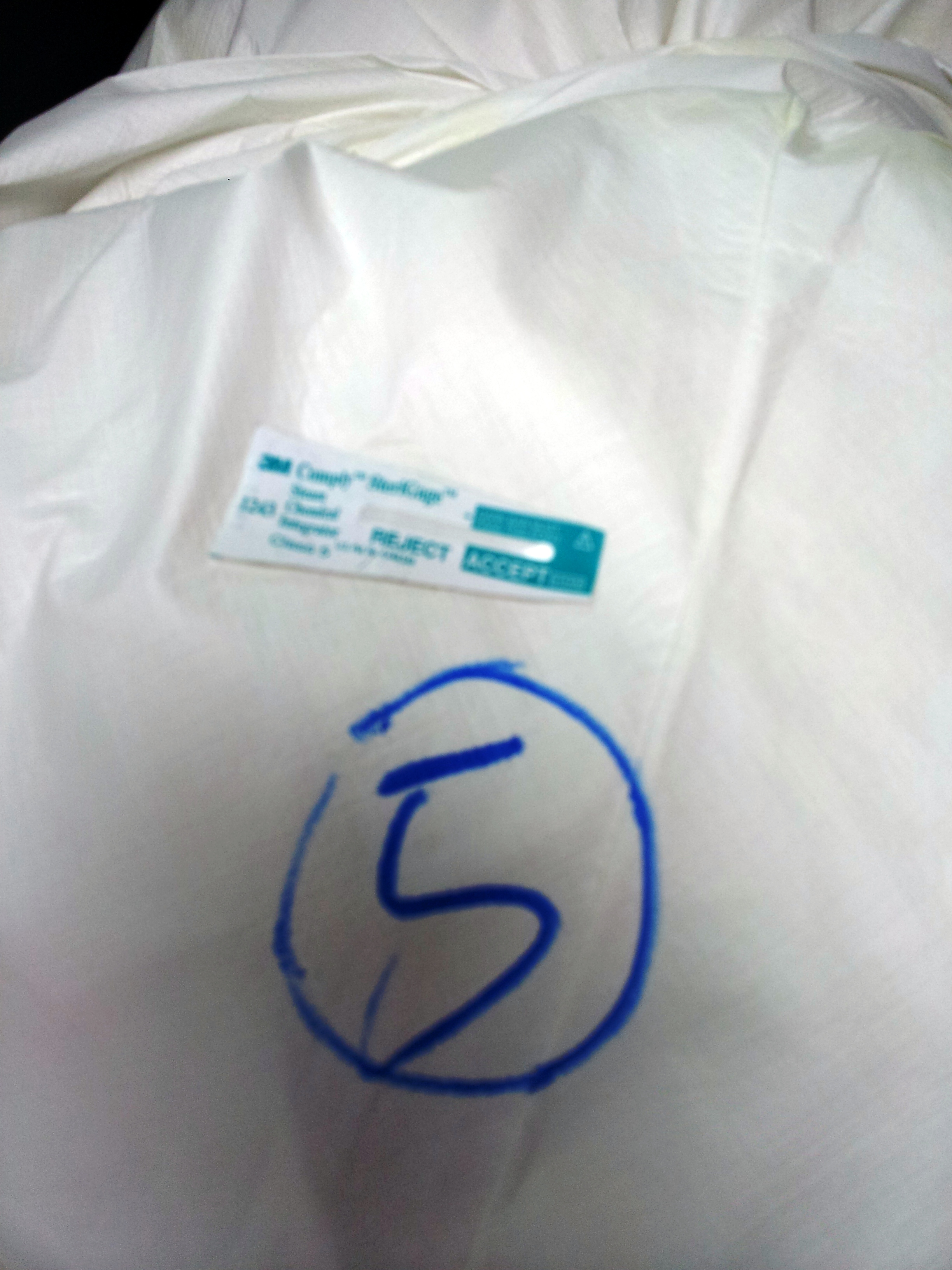

The first gown is wrapped around the load |

A total of 5 gowns are wrapped sequentially |

|

|

|

|

|

| The load is placed in a red bag |

The red bag is sealed |

The red bag is placed inside of the clear liner bag |

The clear bag is tied |

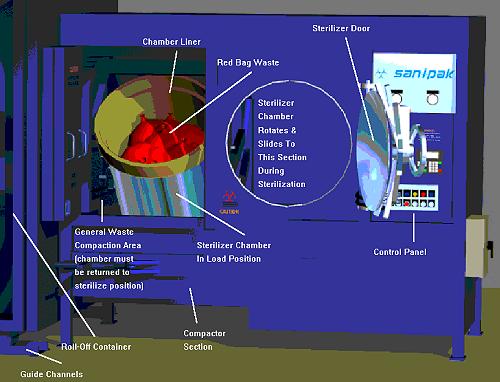

The load is placed in the chamber |

|

|

|

|

|

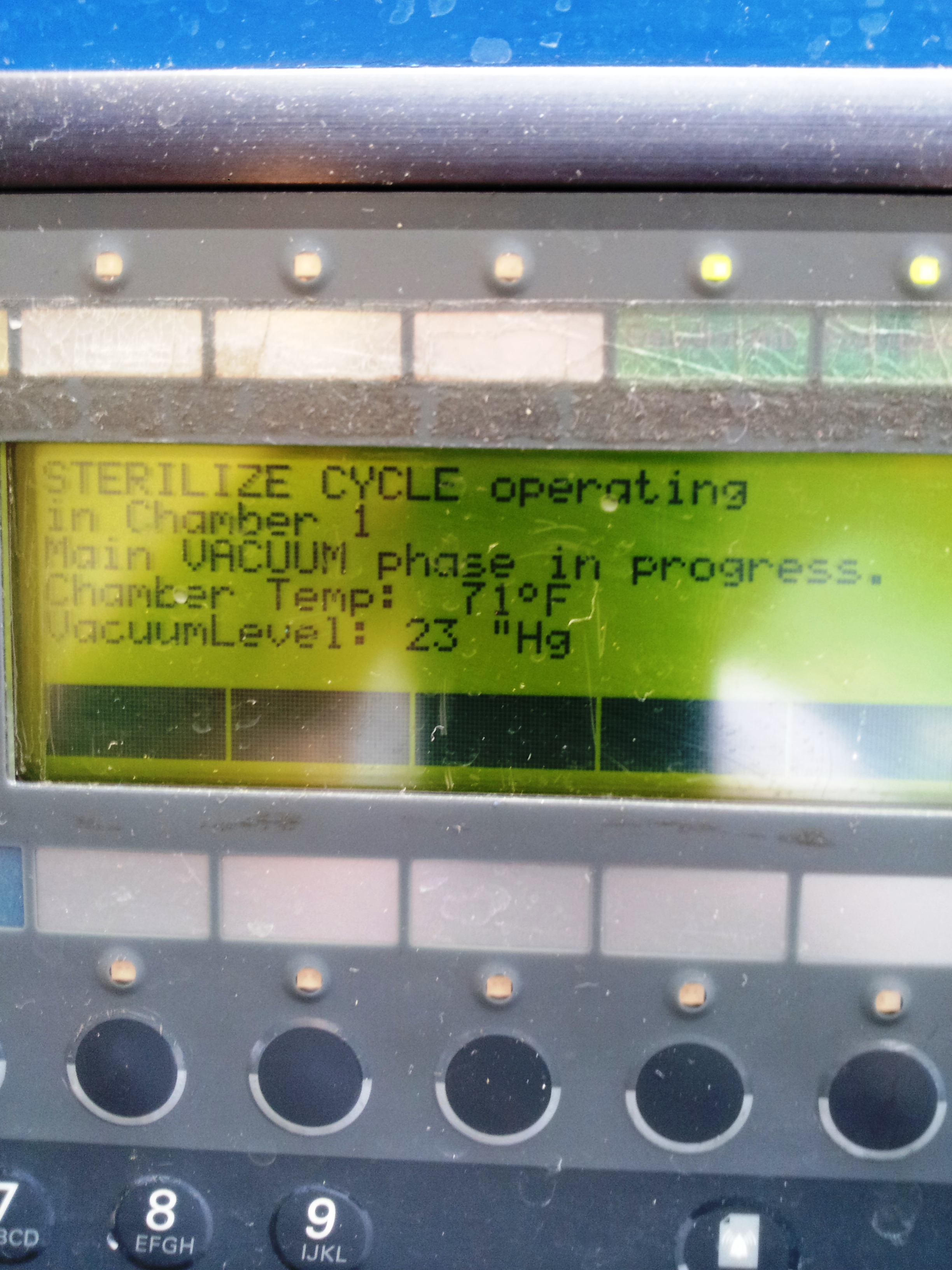

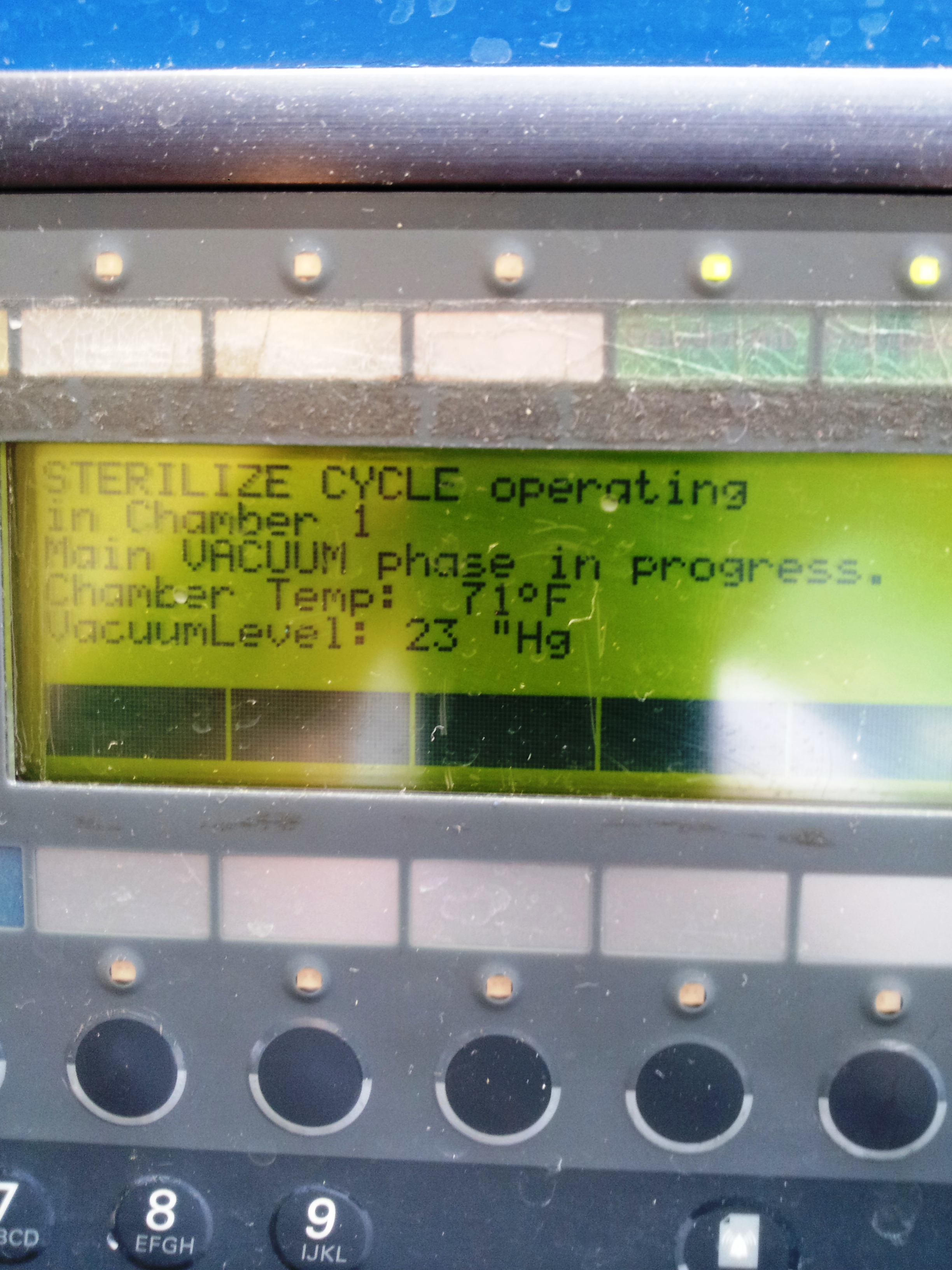

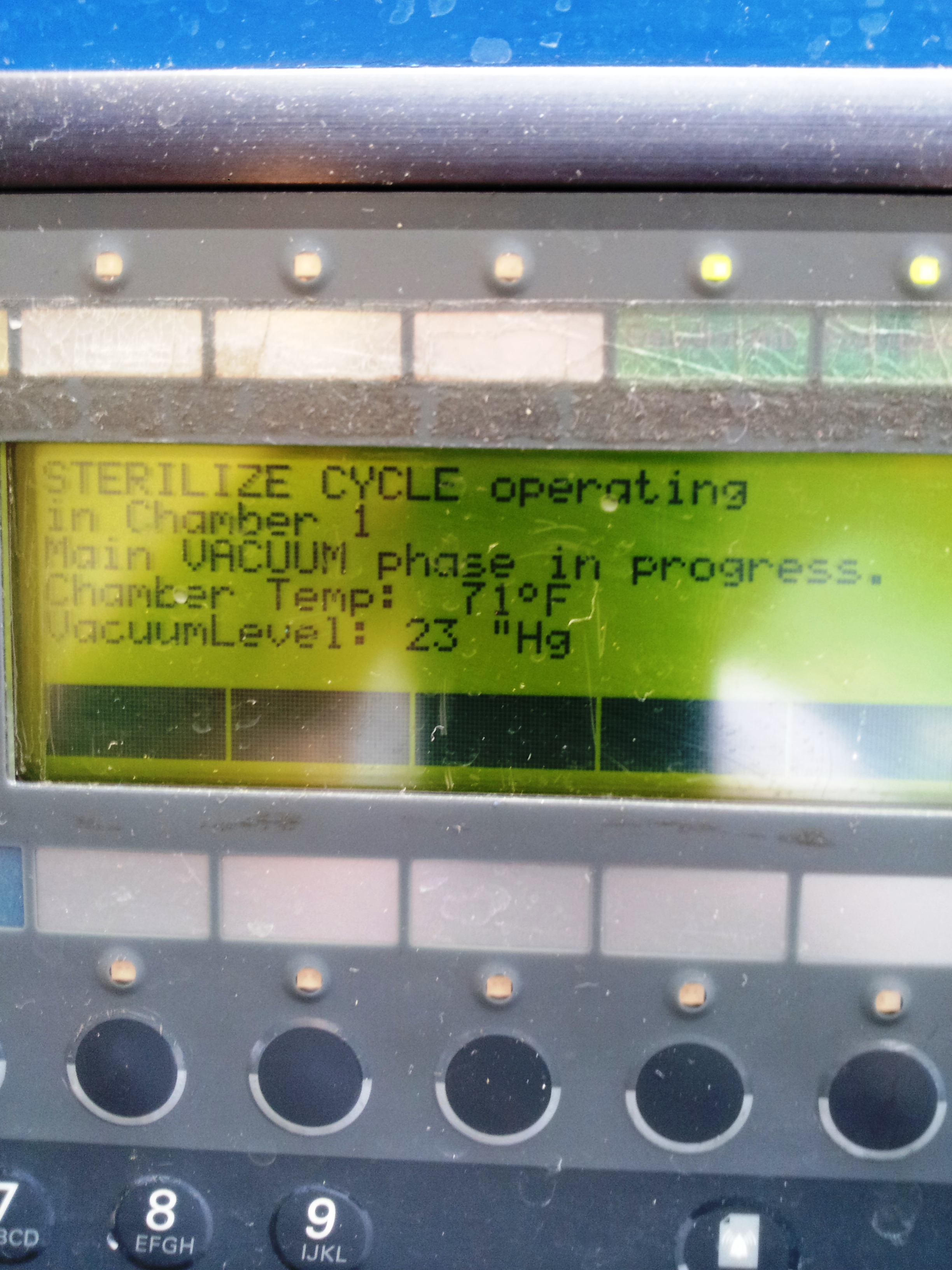

| The initial vacuum is drawn to 24"Hg |

Exposure phase is 40 minutes at 287oF |

Cycle complete |

Red bag was breached. Clear bag was intact |

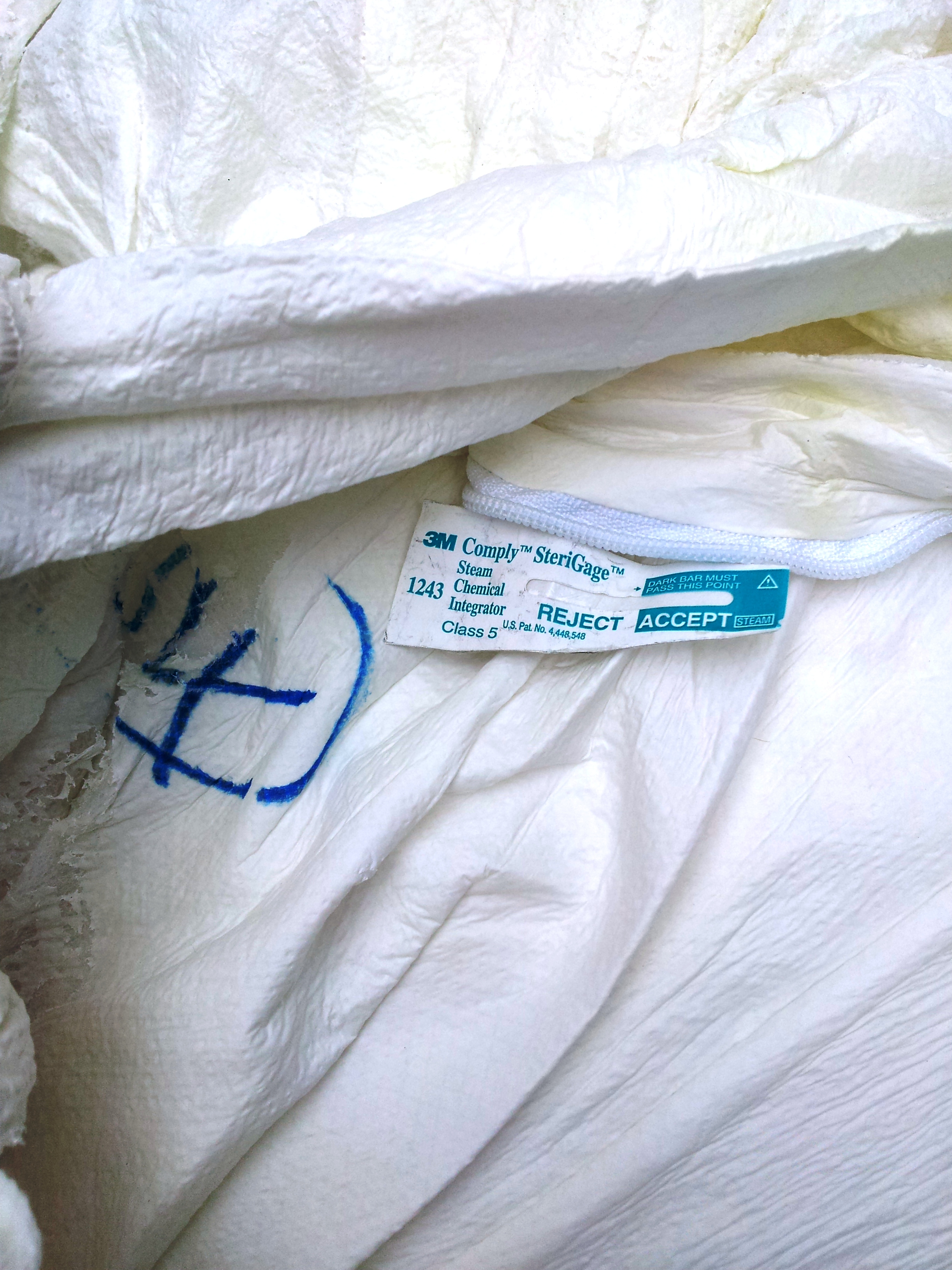

CI at gown layer 4 showed zero exposure |

|

|

|

|

|